Leave Your Message

The production process in the metallurgical industry is continually evolving, with significant emphasis on optimizing efficiency and output. One pivotal component in this optimization is Silicon Manganese, an alloy that has gained prominence due to its beneficial properties in steel production and various industrial applications. According to the International Manganese Institute, the demand for Silicon Manganese is projected to increase by approximately 4% annually, as it plays a critical role in enhancing the mechanical properties and corrosion resistance of steel. Furthermore, utilizing Silicon Manganese can lead to considerable cost savings and improved production rates, as it reduces the need for additional alloying elements. By embracing innovative techniques and methodologies for integrating Silicon Manganese into production processes, companies can not only boost their productivity but also align with the growing sustainability trends in the industry, making it a vital focus area for manufacturers looking to thrive in a competitive market.

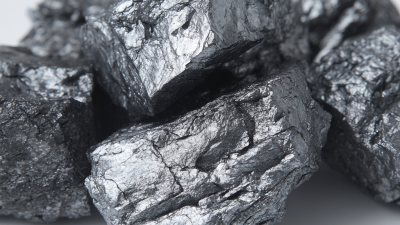

Silicon manganese is a vital alloy in the production process of steel and iron, offering significant benefits for optimization. This alloy combines silicon and manganese in varying ratios, commonly used in steelmaking to enhance the quality and efficiency of production. According to a report by the International Manganese Institute, the incorporation of silicon manganese can lead to a substantial reduction in production costs, estimating savings of up to 15% per ton of steel produced. This is primarily due to its ability to improve the fluidity of molten steel, facilitating better casting and reducing defects.

Furthermore, silicon manganese contributes to higher tensile strength and better ductility in final products. The latest data from the World Steel Association indicate that steel produced with silicon manganese can achieve a tensile strength increase of up to 10%, effectively enhancing the performance of steel in construction and manufacturing applications. This not only improves product reliability but also extends the lifespan of structures and components, thereby optimizing the overall production process. Utilizing silicon manganese is thus a strategic approach for manufacturers aiming to maximize productivity while maintaining product quality in a competitive marketplace.

Silicon manganese has emerged as a vital alloy in the steelmaking industry, playing a crucial role in enhancing the overall quality and efficiency of production processes. Incorporating silicon manganese can significantly improve steel’s mechanical properties while optimizing energy consumption. According to a report by the International Stainless Steel Forum (ISSF), using silicon manganese can lead to a reduction in energy usage by 10-15%, translating into substantial cost savings in large-scale operations. Manufacturers can strategically integrate silicon manganese during the melting phase, allowing for better temperature management and minimizing waste.

Furthermore, incorporating silicon manganese into production processes facilitates improved production rates and throughput. A study conducted by the World Steel Association indicates that steel products with silicon manganese exhibit increased tensile strength and ductility, permitting manufacturers to produce lighter and stronger steel components without sacrificing quality. Implementing silicon manganese not only enhances product performance but also contributes to sustainability efforts within the industry. As steel production becomes increasingly competitive, adopting these strategies will be essential for manufacturers aiming to remain at the forefront of technological and environmental advancements.

Silicon manganese, an essential alloy in steel production, plays a crucial role in enhancing production efficiency. By incorporating this alloy into the production process, companies can significantly reduce energy consumption and improve overall yield. This is because silicon manganese promotes better fluidity in molten steel, reducing the occurrence of imperfections that could lead to material waste.

Silicon manganese, an essential alloy in steel production, plays a crucial role in enhancing production efficiency. By incorporating this alloy into the production process, companies can significantly reduce energy consumption and improve overall yield. This is because silicon manganese promotes better fluidity in molten steel, reducing the occurrence of imperfections that could lead to material waste.

Tips: When integrating silicon manganese into your production line, ensure that you are using high-quality raw materials to optimize alloy performance. Conducting preliminary tests can help gauge the right mix for your specific production needs, allowing for more efficient alloy creation.

Moreover, tracking key performance indicators (KPIs) such as energy usage, output quality, and production speed can provide valuable insights into the impact of silicon manganese on your operations. Regularly reviewing these metrics will assist in adjusting alloy compositions and refining processes to further enhance efficiency.

Tips: Consider employing advanced monitoring technologies to automate data collection. This can facilitate a quick response to any drops in production efficiency, ensuring that corrective measures are implemented promptly.

Silicon manganese is increasingly being integrated into production processes to enhance the quality of steel. However, this integration does not come without its challenges. One common issue is the inconsistent quality of raw materials, which can lead to defects in the final product. To mitigate this, it is crucial to establish reliable suppliers and perform regular quality checks on incoming materials.

Another challenge lies in the adjustment of existing production equipment to accommodate silicon manganese. The high temperatures and varying flow rates may require modifications to maintain efficiency. Investing in training for operators can also upgrade their skill set to handle specific adjustments effectively.

Tips: When dealing with differing material compositions, always consult with your supply chain team to adjust recipes accordingly. Additionally, implementing a feedback loop from operators can help track equipment performance and identify potential issues before they escalate. By proactively addressing these challenges, companies can ensure a smoother transition and optimize their production processes successfully.

To effectively monitor and adjust your silicon manganese usage in the production process, it's critical to establish clear data collection methods. Regularly assessing the levels of silicon and manganese in your materials ensures that you maintain optimal ratios for desired alloy characteristics. Automating these measurements can reduce human error and provide real-time feedback, allowing for quick adjustments to avoid any production pitfalls.

**Tips:** Implement regular audits of your raw material supply and usage metrics. This practice will help identify trends over time and inform necessary tweaks in your process.

Furthermore, consider the integration of advanced analytics tools. By leveraging these technologies, manufacturers can better predict how variations in silicon manganese content will impact the final product quality. This proactive approach not only aids in maintaining consistency but also helps in making informed decisions on inventory management and production scheduling.

**Tips:** Utilize predictive analytics to create simulations of different material combinations and their effects on the product. This can help in optimizing your formulation and ultimately in enhancing overall production efficiency.

| Production Stage | Silicon Manganese Input (kg) | Product Yield (%) | Date of Adjustment | Notes |

|---|---|---|---|---|

| Stage 1 - Mixing | 500 | 85 | 2023-10-01 | Initial Test Batch |

| Stage 2 - Melting | 600 | 90 | 2023-10-05 | Increased efficiency |

| Stage 3 - Casting | 550 | 88 | 2023-10-10 | Consistency check |

| Stage 4 - Cooling | 520 | 87 | 2023-10-15 | Temperature optimization |

| Stage 5 - Finishing | 570 | 92 | 2023-10-20 | Final quality check |