Leave Your Message

The global market for Silicon Carbide Heating Elements is rapidly expanding, driven by increasing demand for efficient and reliable heating solutions across various industries. According to a report by Market Research Future, the Silicon Carbide market is projected to reach USD 1.74 billion by 2027, growing at a CAGR of 20.4% from 2020 to 2027. This remarkable growth is attributed to the unique properties of Silicon Carbide, including its high thermal conductivity, resistance to thermal shock, and ability to operate at elevated temperatures. Leading manufacturers in China are at the forefront of this innovation, showcasing advanced engineering capabilities and strong export tracks worldwide. With an emphasis on quality and sustainability, these manufacturers are not only meeting domestic demand but also establishing a significant presence in international markets, thereby reinforcing China's position as a top player in the production of Silicon Carbide Heating Elements.

The silicon carbide (SiC) heating elements market is witnessing remarkable growth, driven by the increasing demand for efficient and durable heating solutions across various industries. According to recent industry reports, the global SiC heating elements market is projected to reach USD 400 million by 2025, growing at a compound annual growth rate (CAGR) of 8.5% from 2023. This surge can be attributed to the rising adoption of SiC in advanced manufacturing processes and energy-efficient applications.

One of the emerging trends is the integration of smart technologies with SiC heating elements, enhancing operational efficiency and allowing for real-time monitoring. Companies are increasingly leveraging data analytics to optimize heating processes, resulting in reduced energy consumption and improved product quality. The precision offered by these smart heating systems not only contributes to cost savings but also minimizes environmental impact, aligning with the global push for sustainability.

Tip: When selecting SiC heating elements for your application, consider the specific temperature requirements and operational environment. This ensures optimal performance and longevity of the heating systems. Additionally, keep an eye on industry innovations and advancements in materials technology to stay ahead in an evolving market.

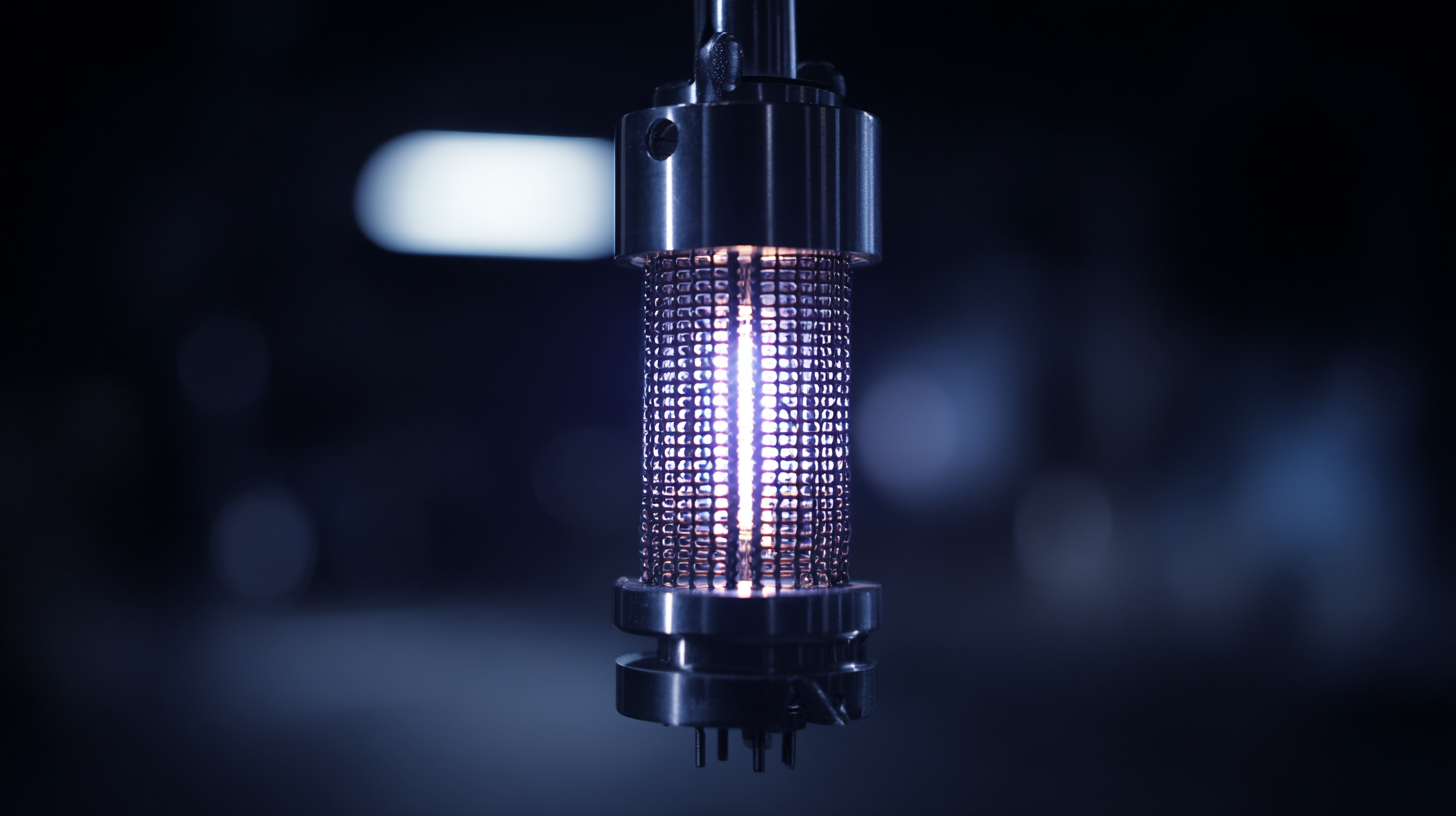

The demand for silicon carbide (SiC) heating elements is surging in 2023, primarily driven by advancements in manufacturing processes and the growing applications in various industries. As industries increasingly prioritize energy efficiency and high-performance materials, SiC heating elements have emerged as a preferred choice due to their exceptional thermal conductivity and durability. Key applications include semiconductor manufacturing, automotive components, and aerospace where high temperatures and precise control are critical.

Furthermore, the advanced ceramics market is expected to expand significantly, projected to reach USD 16.27 billion by 2029. This growth reflects an increasing reliance on advanced materials in sectors that require heat technology, especially as the world shifts toward more sustainable practices and technologies. As companies invest in research and development to explore innovative applications for silicon carbide, the strategic integration of these heating elements is set to be a game changer, positioning them at the forefront of modern manufacturing solutions. The landscape for SiC technology, particularly in heating applications, continues to evolve, emphasizing the need for manufacturers to adapt and innovate.

When it comes to heating elements, the choice between silicon carbide (SiC) and traditional options like metal or ceramic materials has significant implications for efficiency and performance. Silicon carbide heating elements stand out due to their superior thermal conductivity, allowing for faster heat-up times and more consistent temperature distribution. This efficiency translates to reduced energy consumption, making SiC an environmentally friendly choice that can dramatically lower operational costs in industrial applications.

In terms of performance under extreme conditions, silicon carbide exhibits exceptional resistance to thermal shock and oxidation. Traditional heating elements often struggle when exposed to high temperatures over extended periods, leading to premature failure and increased maintenance costs. In contrast, SiC heating elements maintain their integrity and performance in harsh environments, providing a reliable solution for industries that require consistent heat under challenging conditions. This durability not only enhances productivity but also minimizes downtime, making silicon carbide a preferred choice for leading global manufacturers.

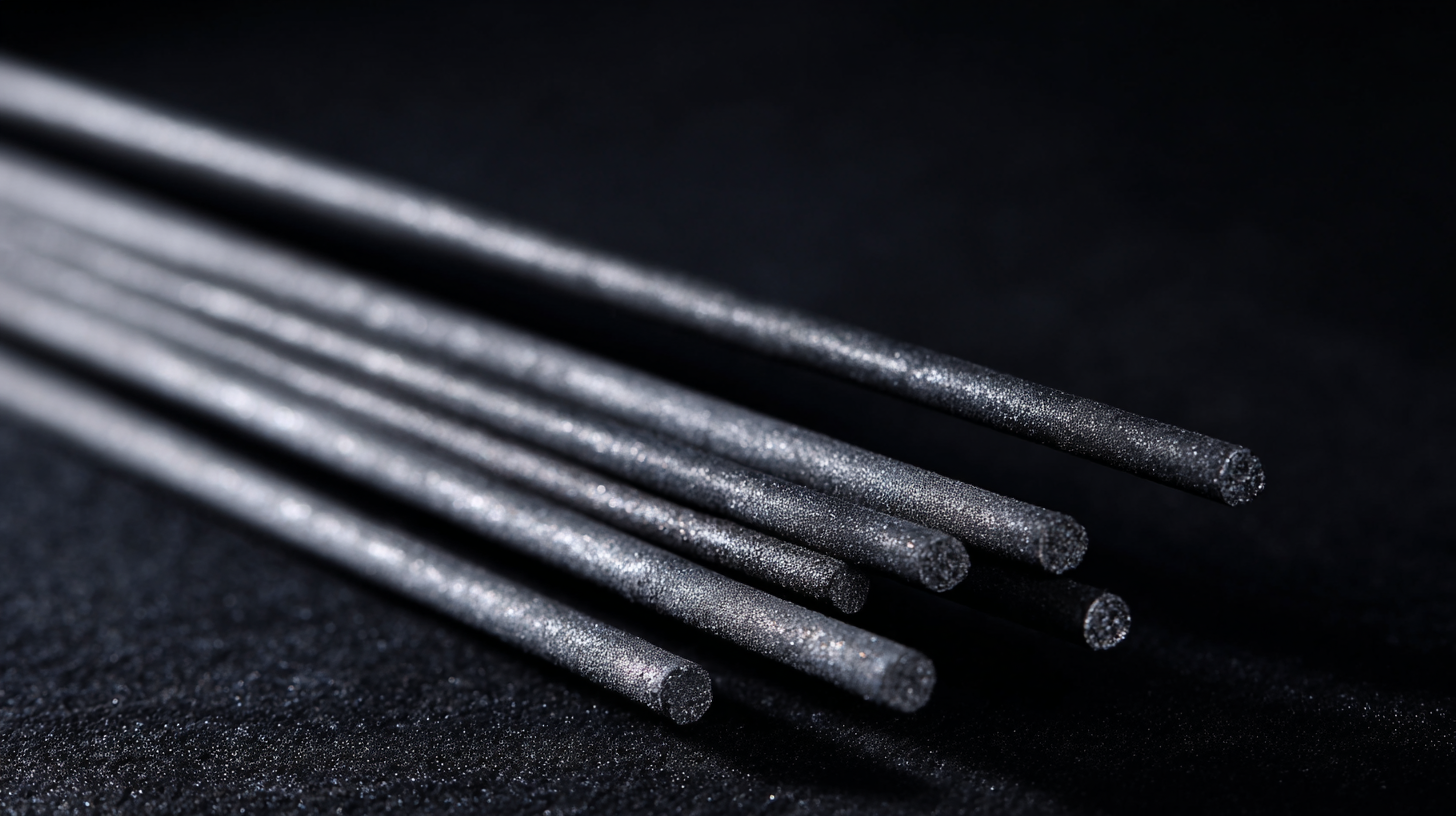

The production cost dynamics of silicon carbide heating elements are influenced by several key factors, including raw material prices, manufacturing technologies, and demand fluctuations.

According to a recent market report by Fortune Business Insights, the silicon carbide market is projected to grow at a compound annual growth rate (CAGR) of 17.5% from 2021 to 2028.

This growth is driving competition among manufacturers, which can lead to fluctuations in material costs.

Silicon carbide is primarily derived from petroleum coke and silica, which are subject to price volatility based on global supply and demand trends.

Moreover, advancements in manufacturing technologies play a significant role in the cost structure of heating elements. The introduction of more efficient sintering techniques, for instance, can reduce production times and costs associated with energy consumption.

A study by ResearchAndMarkets indicates that optimizing manufacturing processes could lead to a 15-20% reduction in overall production costs over the next few years.

As the market continues to evolve, manufacturers that invest in innovative technologies and efficient supply chain management will likely maintain a competitive edge while addressing the cost dynamics inherent to silicon carbide heating element production.

Silicon carbide heating elements are renowned for their durability and efficiency in industrial applications. To maximize their lifespan, it is essential to implement best practices that enhance performance while reducing wear over time.

One effective tip is to maintain optimal operating temperatures. Overheating can lead to premature failure, so it’s vital to balance the heat supply based on the material being heated. Regularly inspecting the heating elements for signs of overheating or thermal stress can help to identify potential issues before they escalate.

Another important practice is to keep the heating elements clean and free from contaminants. Build-up of dust or foreign materials can insulate the elements, leading to uneven heating and potential damage. Regular maintenance checks, combined with a clean environment, will contribute significantly to extending the life of silicon carbide heaters. By following these guidelines, industries can ensure sustained performance and reliability from their heating systems.

This chart illustrates the impact of different maintenance practices on the lifespan of silicon carbide heating elements used in industrial applications.